- Whatsapp:+86 13705146579

- Telephone:13705146579

- Wechat:DLBB1228

- Email:info@flexkys.com

- Address:Room 308, Building 4, Tongce Tongde Park, 100 Jiuzhu Road, Jiangning District, Nanjing, Jiangsu, China

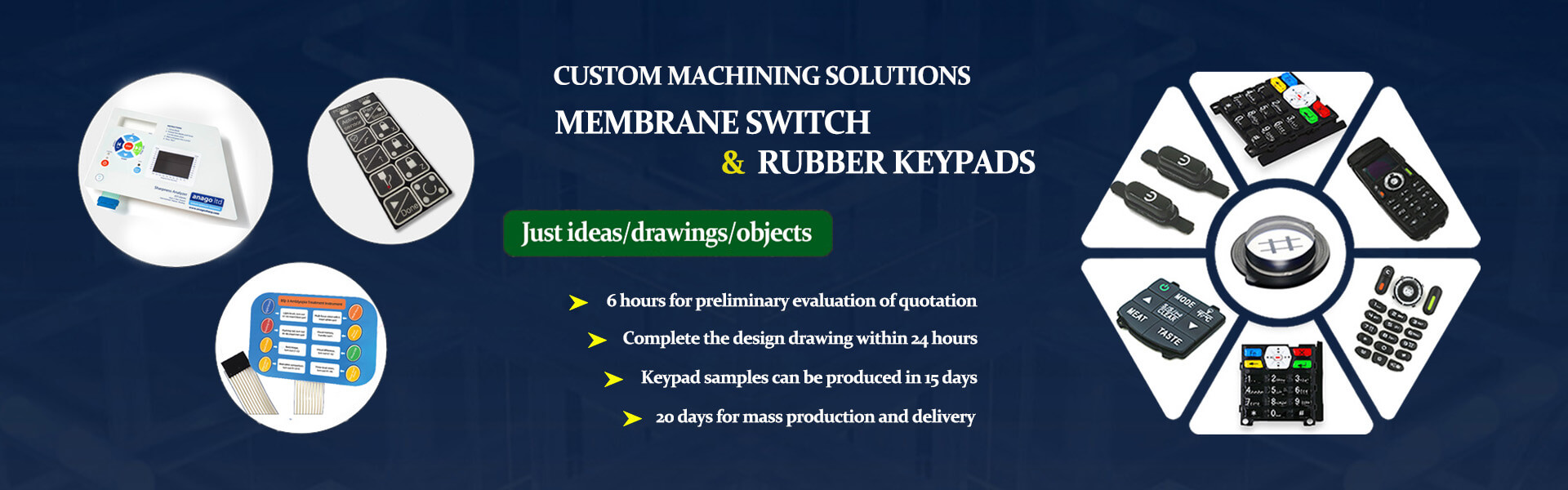

How to design membrane switch?

Source: FLEXKYS Editorial Office Release time:2022-09-01 09:40 Click:

A. Analyze product requirements

A-1. Where is membrane switch used for?

A-2. What is the application feature?

A-3. The using environment of membrane switch

B.What we need prepare

|

|

Art work drawing |

Dimension |

Circuit Schematic |

Specification |

Requirement |

|

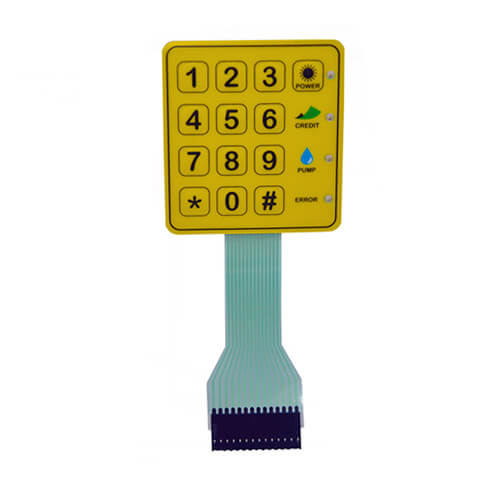

Membrane panel |

√ |

√ |

× |

⃝ |

√ |

|

Membrane switch |

√ |

√ |

√ |

√ |

√ |

|

Flexiable circuit |

× |

√ |

√ |

√ |

√ |

|

Capacitive Sensor |

× |

√ |

√ |

√ |

√ |

|

FSR |

× |

√ |

⃝ |

× |

√ |

|

IMD |

√ |

√ |

× |

⃝ |

√ |

|

Rubber keys |

√ |

√ |

× |

⃝ |

√ |

√ Needed × Needless ⃝ Not essential

C.The available drawing files format

D.The designing points of membrane switch

Recommended products MORE+

-

Capacitive Touch Membrane Switch

-

Mini key transparent window Membrane Switch keypad

-

Two keys UV and water proof outdoor LED Membrane S

-

Anti-UV and waterproof outdoor use membrane switch

-

Silver esd Shielding layer metal dome embossing ke

-

Medical Instruments Membrane Swith with Aluminium

-

Two keys UV and waterproof outdoor LED Membrane Sw

-

Washing Machine Waterproof Membrane Switch Keypad

Technical support MORE+

- Membrane Switch Mounting and Operation 2022-09-15

- Product Material 2022-09-15

- Capacitive Touch Switch 2022-09-02

- PCB membrane switch 2022-09-01

- Waterproof membrane switch 2022-09-01

- How to design membrane switch? 2022-09-01

- Metal dome membrane switch 2022-08-31

- P+R Keypad Product Presentation 2022-08-31

- Operating guidance of membrane switch 2022-08-22

- Poly dome membrane switch 2023-01-31