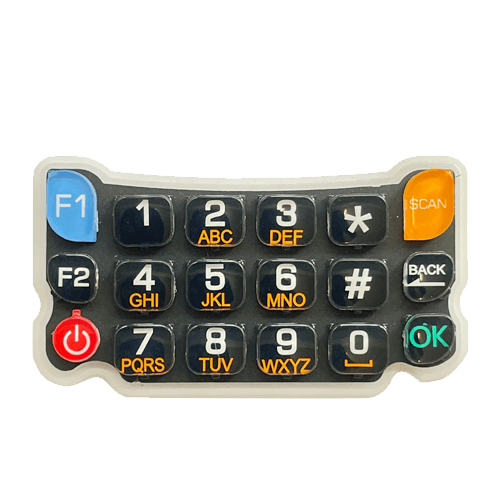

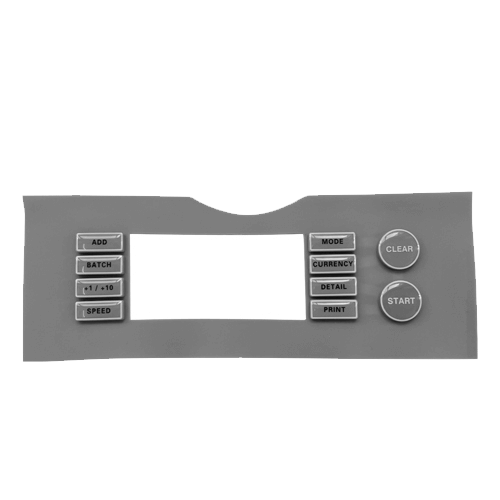

P+R Silicone Keypad

P+R silicone keypad introduction

Combining plastic keycaps (P) and rubber silicone bases (R) results in a high-performance system known as the P+R Silicone Keypad. Medical devices, industrial controls, consumer electronics, and other fields all make extensive use of this kind of keypad. The plastic keycaps are completely bonded with the silicone base through the use of sophisticated injection molding technology, providing the ideal ratio of comfort, functionality, and durability.

Why to choose P+R silicone keypads?

The P+R Silicone Keypad is the best option for contemporary gadget designs because it provides the optimal balance of durability, functionality, and esthetics. Our keypads enhance the value of your products and satisfy the needs of many industries thanks to their excellent craftsmanship, exceptional tactile feel, and flexible applications.

P+R silicon keypad’s features

Plastic Keycaps (P)

Precise dimensions for a pleasant tactile feel, high-strength plastic for superior wear resistance, and surface treatments that can be customized.

Silicone Base (R)

A high-quality silicone substance with elasticity, flexibility, and resistance to heat, dust, and water.

P+R Integration Technology

A solid and smooth connection between the silicone base and the plastic keycap is guaranteed by sophisticated injection molding.

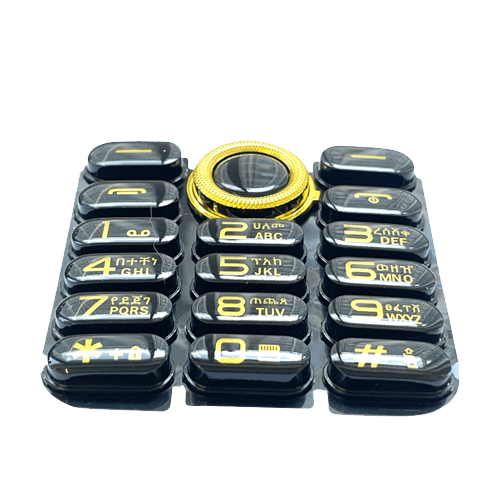

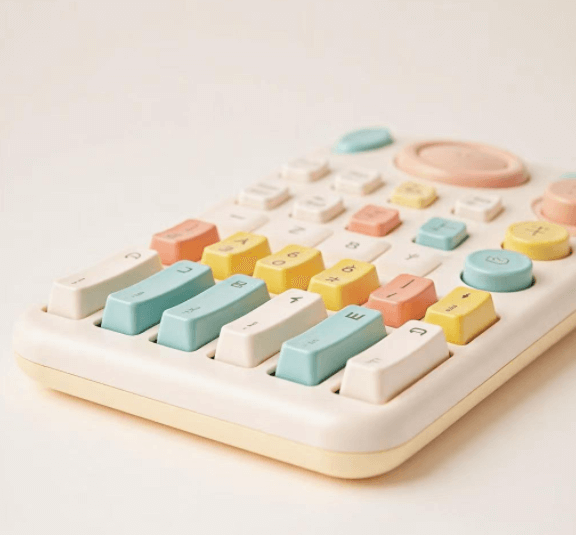

Customizable Options

Allows for the creation of unique characters, colors, backlighting effects, and functional designs based on user requirements.

Durability and Eco-Friendliness

Ensures a long lifespan and complies with international environmental requirements by combining the flexibility of silicone with the wear resilience of plastic.

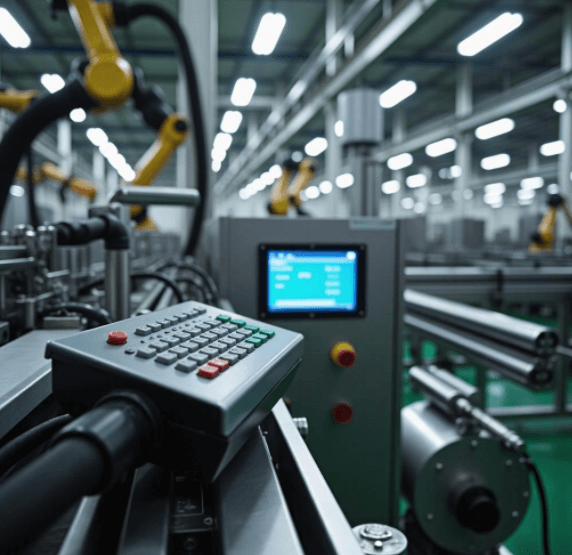

P+R keypad produtction process

To guarantee excellent quality and longevity, the P+R Silicone Keypad is produced using a number of exacting and sophisticated manufacturing processes:

Applications

Consumer Electronics

Remote controls, keyboards, game controllers and more.

Industrial Equipment

Control panels, instrument keypads and other industrial applications.

Medical Devices

Diagnostic equipment, monitoring device keypads and more.

Automotive Electronics

Central control buttons, in-car device panels and more.

Communication equipment

Telephone, mobile phone keyboard.