IMD/IML Product Center

IMD / IML part Introduction

IMD In Mold and IML In Mold Labelling are advanced manufacturing technologies that directly integrate decoration and functionality into the molding process.

These technologies are widely applied in industries such as consumer electronics, automotive interiors, household appliances and medical equipment.

IMD/IML has many advantages, including high durability, scratch resistance, chemical resistance and customizable design.

These features make IMD/IML highly suitable for creating high-quality, esthetically pleasing and durable products.

Learn more about the IMD process to gain a detailed understanding of its applications and advantages.

IMD/IML Products

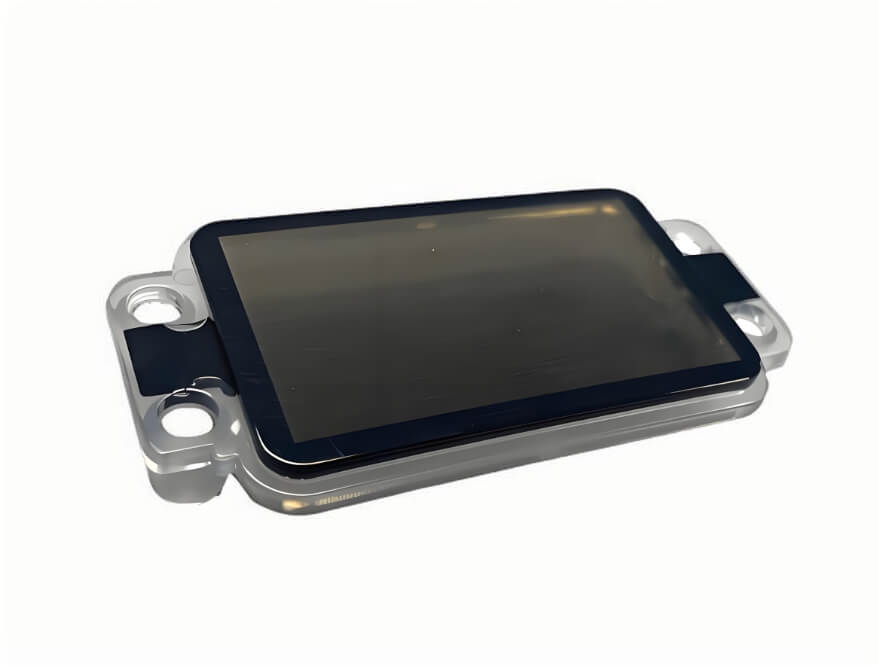

1.Display Window IMD Part

2.Complex-shaped IMD part

3.Digital printing IMD part

4.Hidden display IMD Part

Application Fields

Consumer electronics

such as phone covers and smart home panels

Automotive interiors

e.g., dashboards, control panels

Home Appliances

e.g., washing machine and refrigerator panels

Medical devices

such as operating panels, display decorations

Others

Electric Lock,Electric toothbrush, electric shaver,toy,powder compact

OEM Services

Process for OEM Service

—— Original Equipment Manufacturer ——

Step 1

Customer demand Analysis

Step 2

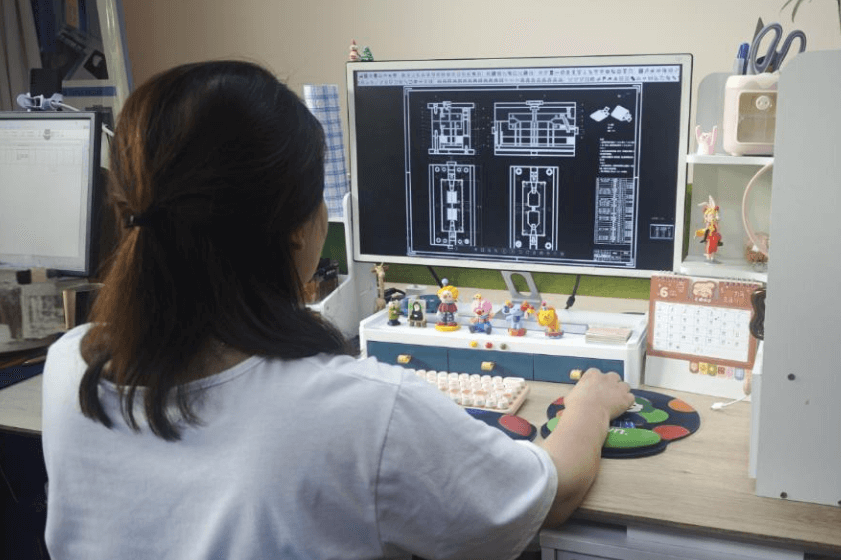

Mold Design and Development

Step 3

Sample Production

Step 4

Small Batch Production

Step 5

Mass Production

OEM Service Advantages

—— Original Design Manufacturer ——

Precision Mold Development

High Efficient Production Cycles

Strict Quality Control System

Flexible Customization Services

Competitive Price

ODM Services

ODM Service Process

-Original Design Manufacturer

Step 1

Feasibility Analysis

Step 2

Appearance Design and Function Development

Step 3

Samples Production and Verification

Step 4

Mass Production and Optimization

Benefits of ODM Services

Library of Rich Design Templates

Reduced Customer R&D Time

Efficiency Gains and Cost Optimization

Full-Service Technical Assistance