PCBA Product Center

FLEXKYS is a professional PCBA control board R&D and manufacturing enterprise, with an experienced hardware design and embedded software development team. It can provide full-process services including PCB design, key component selection, firmware development, prototype production, and mass production according to the project requirements of customers.

We have accumulated over a hundred successful solution cases in fields such as small household appliances, automotive equipment, smart home, consumer electronics, and industrial control, providing customers with one-stop solutions from creativity to mass production and implementation.

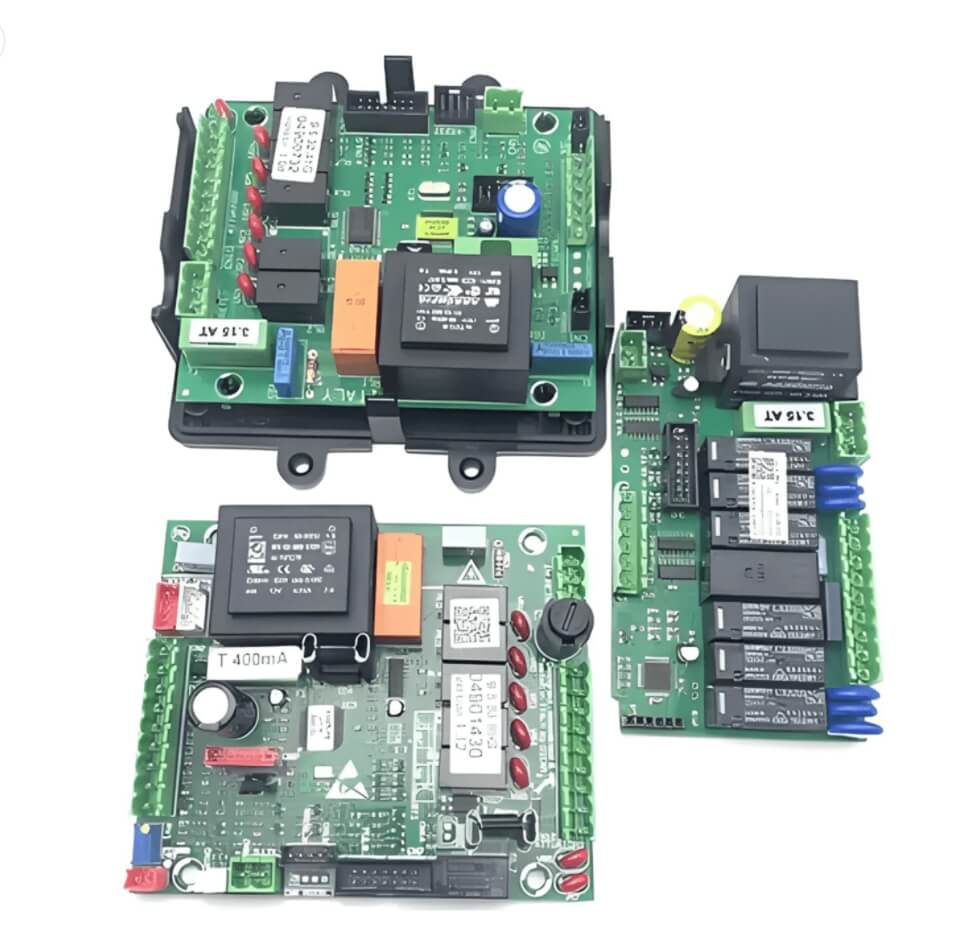

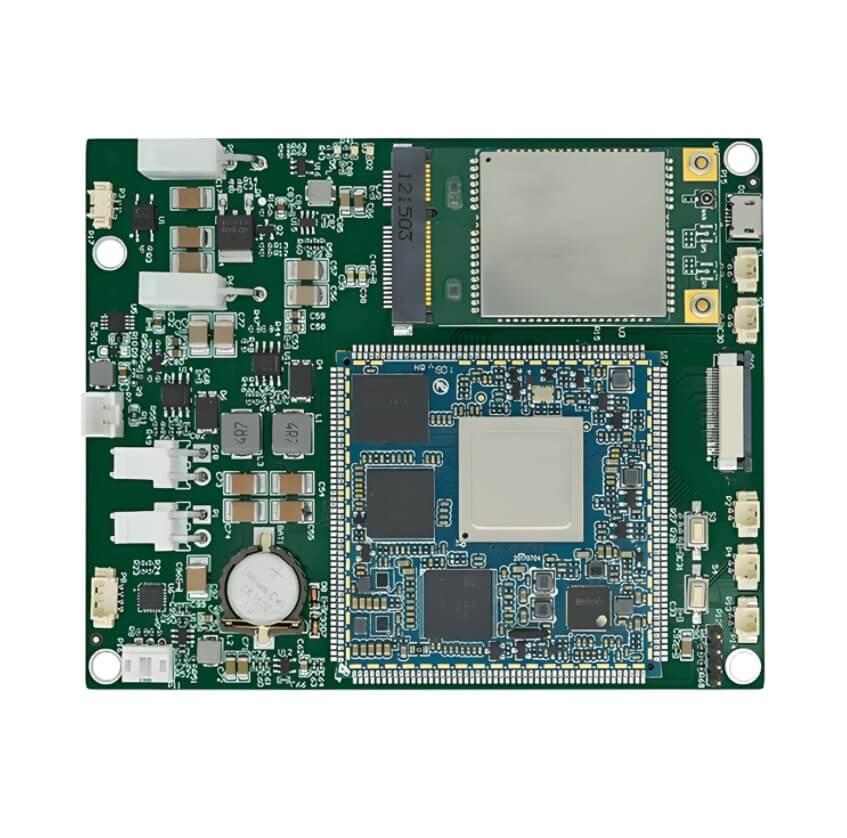

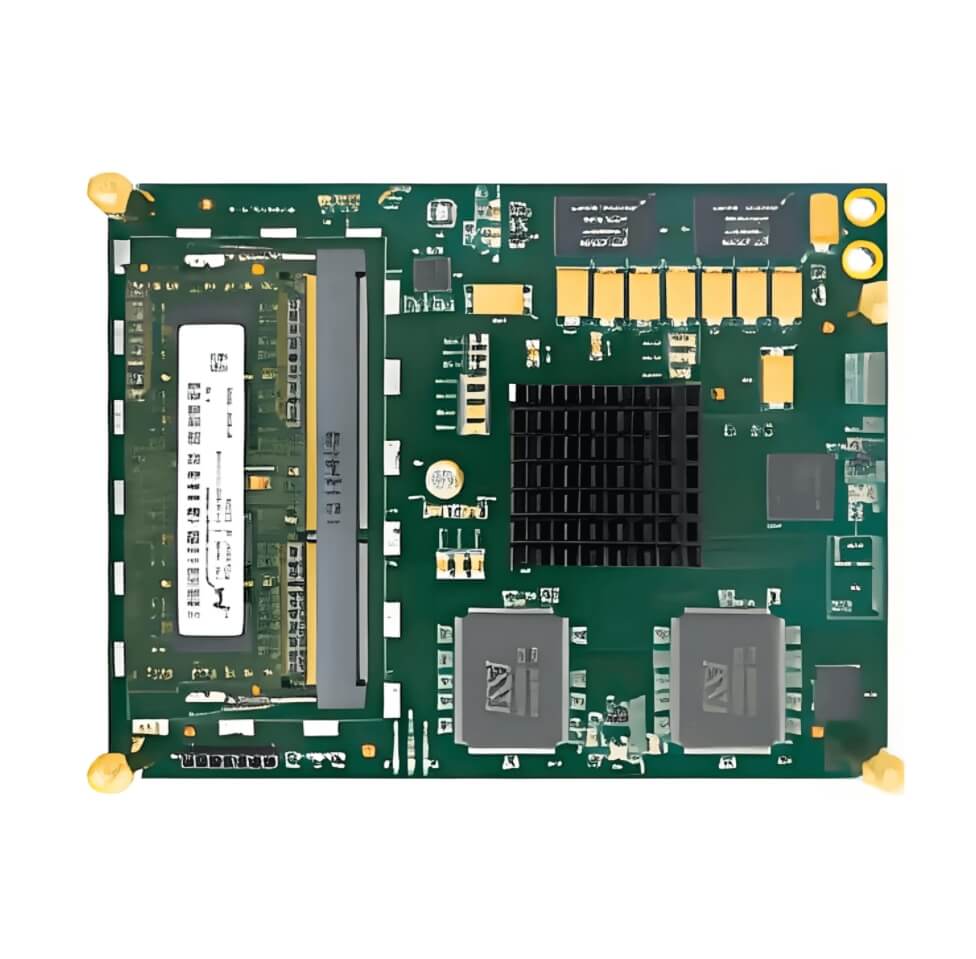

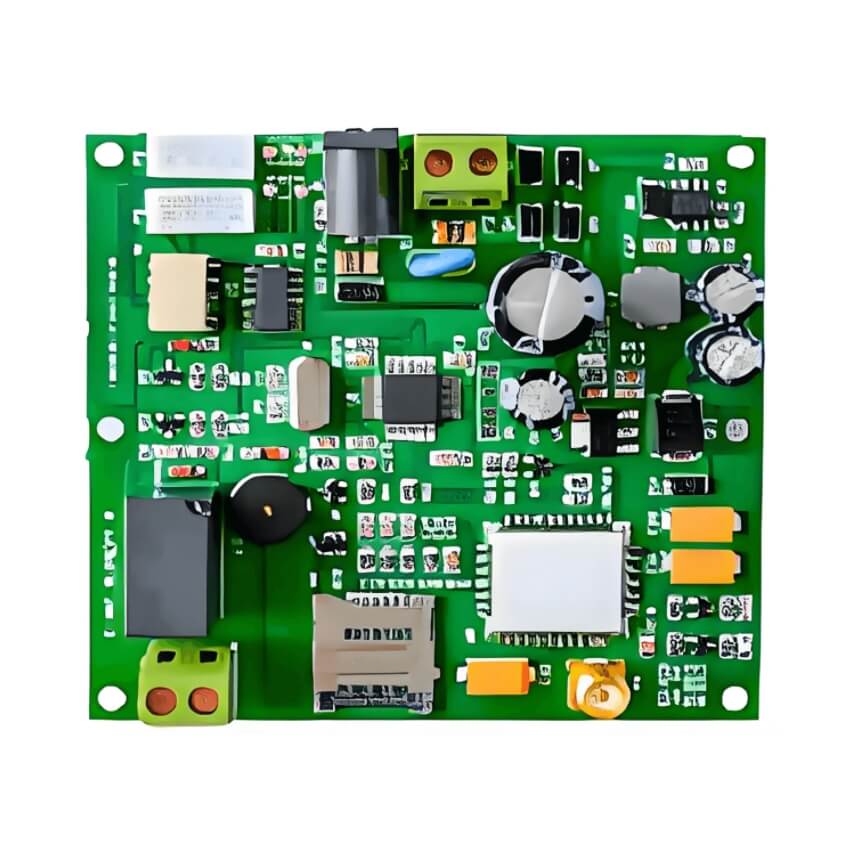

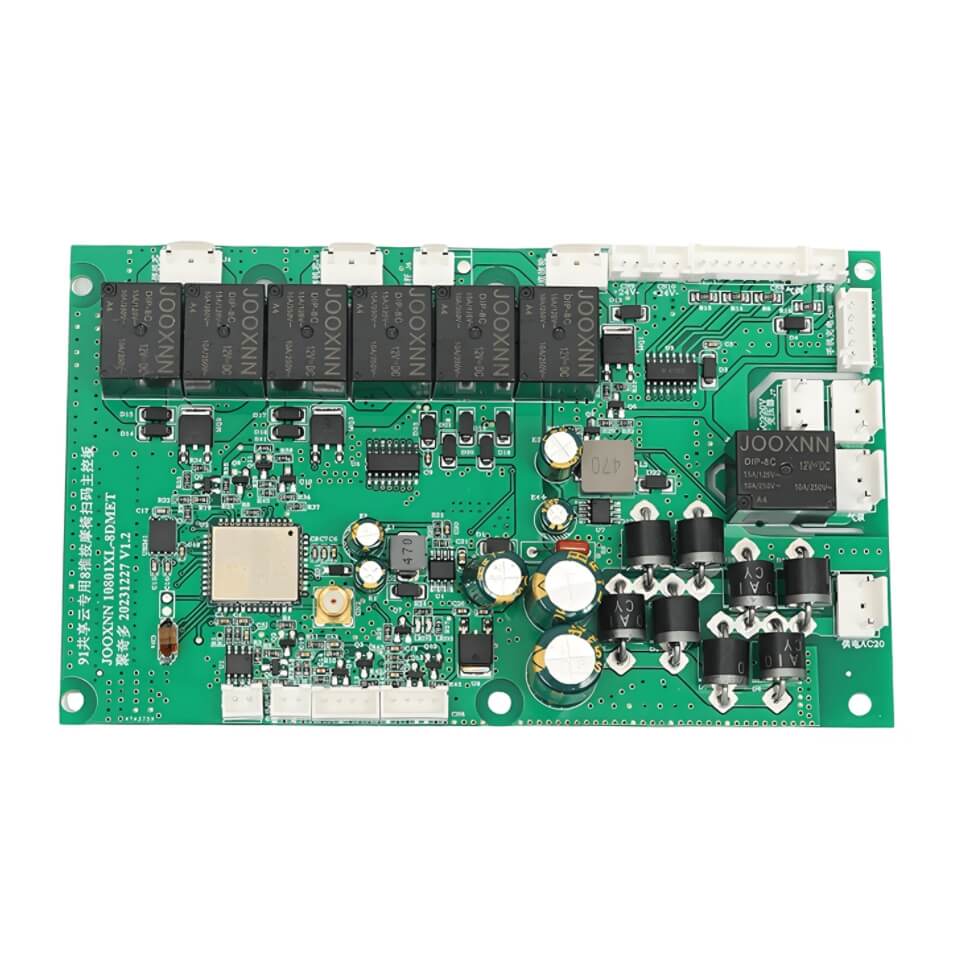

The projects made by FLEXKYS

Coffee machine PCBA

Handheld air meter PCBA

Pet locator PCBA

Pulmonary capacity testing instrument PCBA

Treadmill PCBA

Coffee machine PCBA

Service process & technical solutions

/01

Requirements clarification

Identifying customers’ requirements for products core functions, connectors, standards, and certificates through extensive customer interactions.

/02

Schematic and PCB Design

For each project, a professional hardware team provides customized circuit designs and PCB layouts, including multi-layer boards, HDI, and complicated special-shaped structures.

/03

Prototype Development and Component Selection

Based on real-world applications, we may suggest appropriate MCUs, sensors, communication modules, and power components , achieving a balance of performance and cost.

/04

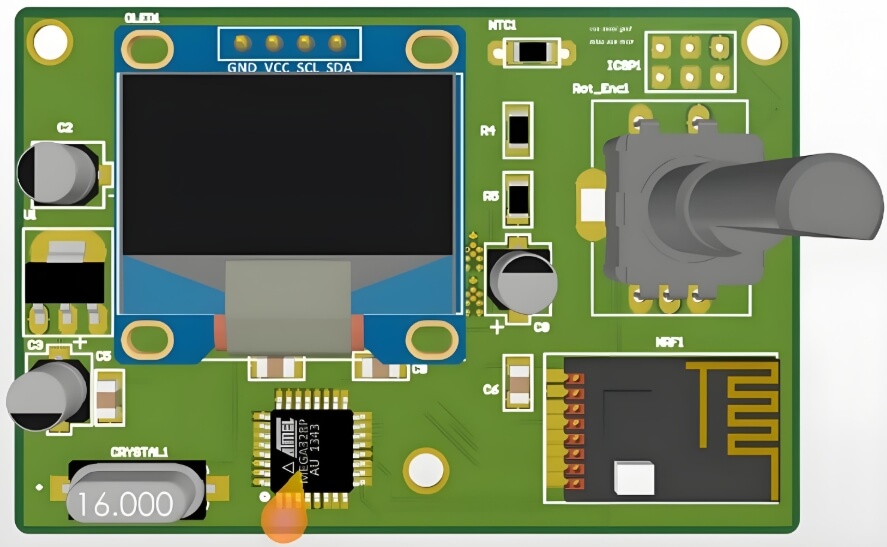

Embedded Software Development

Depending on the needs of the project, an experienced engineer team can create embedded firmware in C/C++, RTOS, Bluetooth, and other technologies.

/05

Rapid Proofing and Testing

Our own SMT production line is capable of producing high-quality prototypes, carrying out comprehensive functional testing and reliability verification.

/06

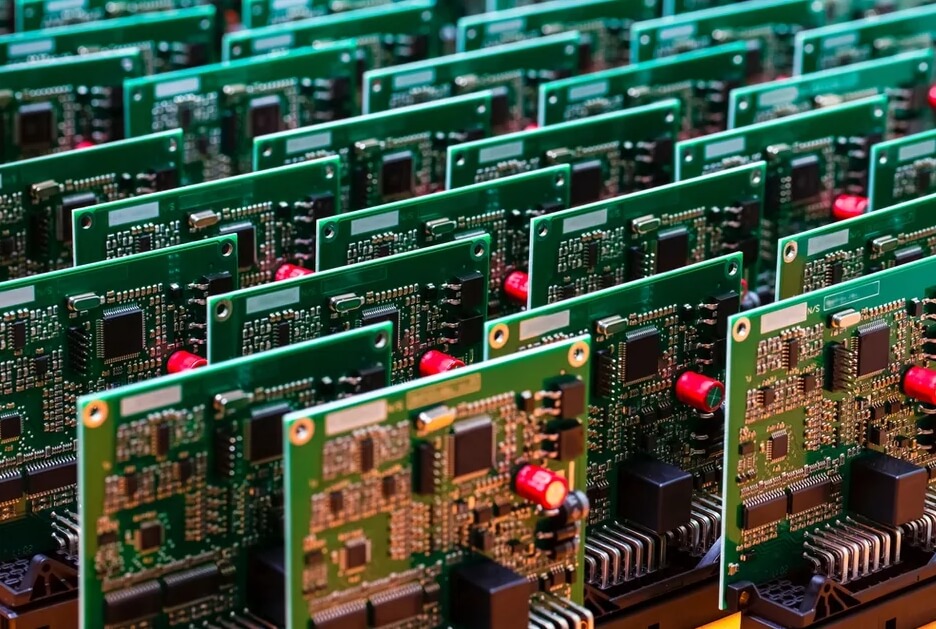

Mass Production Optimization and Supply Chain Management

We can optimize BOM materials and manufacturing line processes based on batch needs, resulting in high consistency and first-pass rate delivery.

/07

Continuous After-sales Service and Technical Support

We will continue to pay attention to the on-site performance of batch products applications and respond promptly to customer upgrade and function expansion needs.

Embedded R&D customization

Start a New PCBA Project!

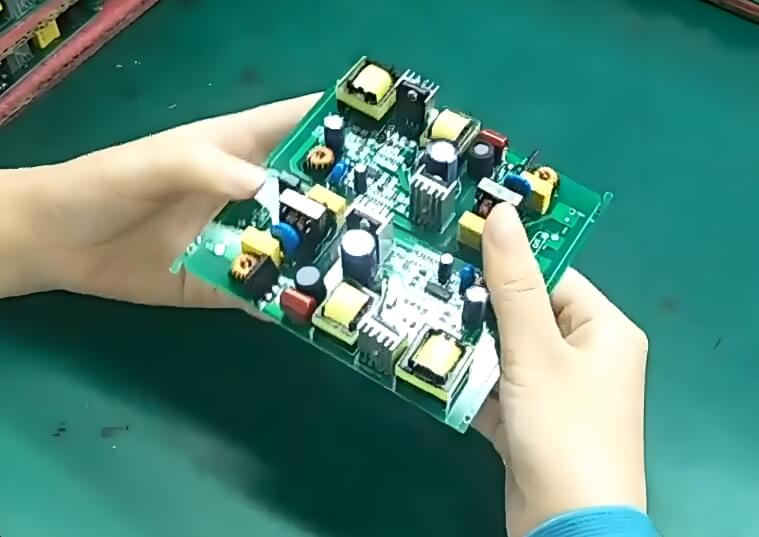

Our PCBA workshop video

Sample & mass delivery assurance

Our own high-speed SMT placement, plug-in, and assembly lines support both small-batch customization and mass production in the millions.

Advanced AOI, X-Ray, and ICT testing equipment guarantees thorough quality control.

MES data traceability, the core process, ensures yield rate and controlled delivery.

Quick response to customers’ on-site technical services and batch upgrade needs.

PCBA process capability

|

Item |

Process Capability |

|

Minimum Line Width and Line Spacing |

≥3/3mil (0.076mm) for finished copper thickness <5Z; |

|

Minimum mechanical hole diameter |

0.20mm |

|

Minimum laser hole diameter |

0.10mm |

|

Minimum BGA pitch |

0.20mm |

|

Minimum SMD Component Size |

01005 |

|

Mounting accuracy |

Chip ±28 microns @Cpk≥1.0; |

|

Mounting speed |

40,000 points/hour/machine |

|

Impedance control tolerance |

Single-ended or common-mode single-ended impedance can be controlled within 45~85 ohms; |

|

Peak First-Pass Yield |

100% for simple processes; |

|

Maximum PCB Size for Mounting |

600*400mm. |

|

Maximum Number of Layers Supported |

1-27 layers (mass production capability up to 16 layers, sample production capability up to 27 layers). |

|

Buried Resistor and Capacitor, Thick Copper, and Special-shaped Board Production |

Buried resistor and capacitor are not supported. Thick copper and special-shaped board production and assembly are possible. |

|

Mixed Assembly Process |

SMT+THT process mixing is possible. COB bonding process is not supported. |

|

Automated Inspection |

100% AOI (Automated Optical Inspection) and SPI (Solder Paste Inspection) are available. |

|

Testing Capabilities |

ICT/FCT functional testing is available through dedicated test fixtures. X-Ray inspection requires collaboration with specialized inspection vendors. |