Product introduction

Keyword

membrane switches,FPC membrane switches,circuit membrane switches,printed circuit membrane keypad,copper membrane switch,copper flex Membrane Switches,FPC membrane keypad.

Specification

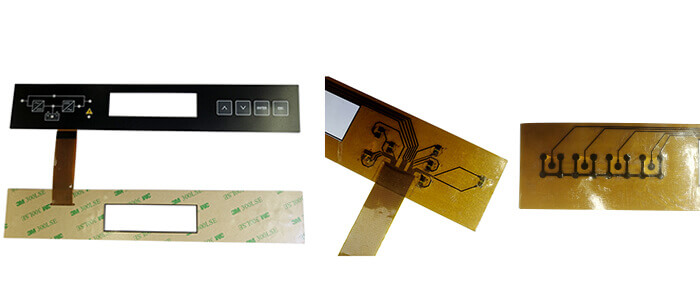

Outer dimension: 237*39.8mm

Graphic overlay: F200

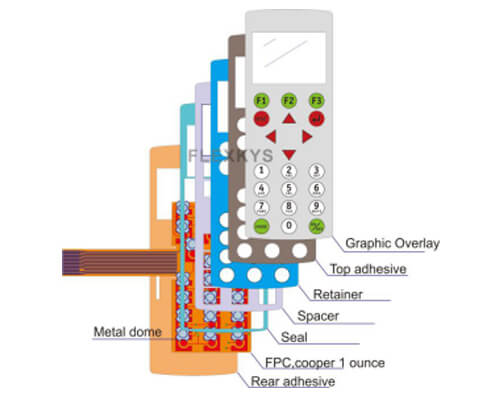

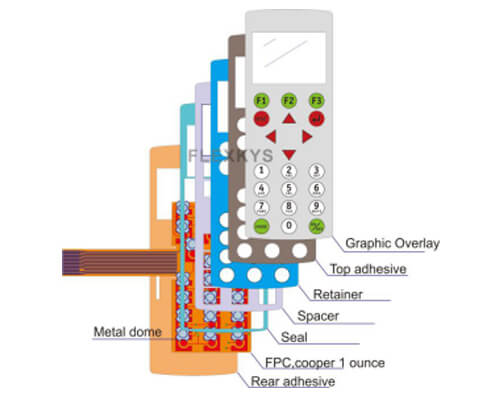

Key type: Metal dome

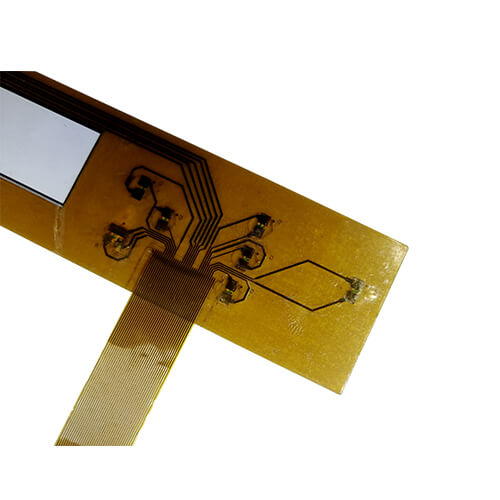

Circuit: copper printed circuit FPC circuit

Back adhesive: 3M300 LSE

Led: bi-color yellow-green led 0603 *7pcs, red led 0603*1pcs

Connector: 0.5mm pitch with stiffener

The circuit of membrane switches can be flex and rigid. It depends on the customer end application and also related to the cost budget and other considerations. For example, life, resistance, connection type on main board etc.

For the flex circuit membrane switches, there are two types: Silver printed PET circuit and copper etched FPC circuit.

Their difference and advantages & disadvantages are listed bellow:

If you don’t know how to choose, please kindly contact FLEXKYS to give you best suitable solution.

| Items | Silver Printed Circuit | Copper Etched FPC Circuit |

| Material | PET (Polyester) | Polyimide |

| Conductor | Printed silver | Copper |

| Contact Fingers | Silver and Carbon | Gold plated |

| Contact Buttons Pads | Silver | Gold plated |

| Life & Reliability | normal | good |

| Stability | normal | good |

| Resistance | Normal | Very low |

| Cost | low | high |

| Lead Time | 12-15 working days | 12-15 working days |

| Pitch | 1.0mm,1.27mm,2.54mm | 0.5mm, 1.0mm,1.27mm,2.54mm |

If you don’t know how to choose, please kindly contact FLEXKYS to give you best suitable solution.

Structure presentation

FPC membrane advantages compared with silver film switch

①Low resistance(10% of silver film switch)

②load large current(Normally 1Acurrent/0.5mm line)

③Components(LED and resistance)can be welded more firmly

④Good oxidation resistance, suitable for humid environment

⑤The connector at the end of cable can be made to smaller to save space.

Normal material:

(1)Graphic overlay material:

| Finish | Specification | |

| PC(polycarbonate) | Gloss | 0.175/.25/.35/.5 mm thickness |

| Matt | 0.175/.25/.35/.5 mm thickness | |

| PET (polyester) | Fine Texture | 0.15/.20 mm thickness (Autotex F150/F200, imported) |

| Velvet Texture | 0.15/.20 mm thickness (Autotex V150/V200, imported) | |

| Gloss with Hard Coat | 0.18 mm thickness |

(2)FPC:

1. ounce copper,total thickness 0.135~0.15mm

2. back adhesive material:3M467, 3M468, 3M9080A or others alternative

3. connector alternative :female:2.54mm;ZIF 1.0mm,ZIF 0.5mm or others specified

Working environment

Temperature:-20~80℃

Humidity:40℃,RH <95%

Electrical performance

Circuit voltage:DC 50V MAX (others need meet components)

Circuit current:1A MAX

Closed circuit resistance:normally <10 ohm(details see products designing and circuit length)

Button working life:>0.5 million times

Response time:<10 mS

Notice on mounting and operation

①Clean up the surface where the switch is bonded and make sure it is flat,without rust,oil and dust.

②Compare the size to membrane switch where need be stick ,check if position is correct.

③Tear off 10mm length of the bottom release paper from side.

④ Put the tail through the back board. Please do not pull the tail with force. The minimum bending radian of the lead wire is R=2mm. The hold edge must smooth in case of damaging the tail.

⑤Align the panel with the sticking place and press on the fixed part, then slowly remove the rest release paper and flat the panel.

⑥The stick process is finished in one time.Switch can not be repeated stick.

⑦Please make sure the bending angel of panel is lower than 15 degree when sticking.

⑧Please do not pull the connector so hard when in connection. For female connector, please hold the house when in connector.

⑨Do not pull the lead wire directly. For FPC( Flexible printed circuits) structure, please unlock the socket before plugging.

⑩Note:To assure the switch life,please put it on the table flatly when testing the hand feeling.Do not pinch the button when holding it on hand.

SPEAK WITH ONE OF OUR SPECIALISTS

MEMBRANE SWITCH

Technical support

- What are the production processes of silicone keyp

- How do manufacturers customize silicone key panel

- Membrane Switch Mounting and Operation

- Product Material

- Capacitive Touch Switch

- PCB membrane switch

- Waterproof membrane switch

- How to design membrane switch?

- Metal dome membrane switch

- P+R Keypad Product Presentation

Contact us

- Whatsapp:+86 13705146579

- Telephone:13705146579

- Wechat:DLBB1228

- Email:info@flexkys.com

- Address:Room 308, Building 4, Tongce Tongde Park, 100 Jiuzhu Road, Jiangning District, Nanjing, Jiangsu, China